Key Points of Daily Maintenance of Conveyor Belt

Key Points of Daily Maintenance of Conveyor Belt

I. Daily Inspection Items

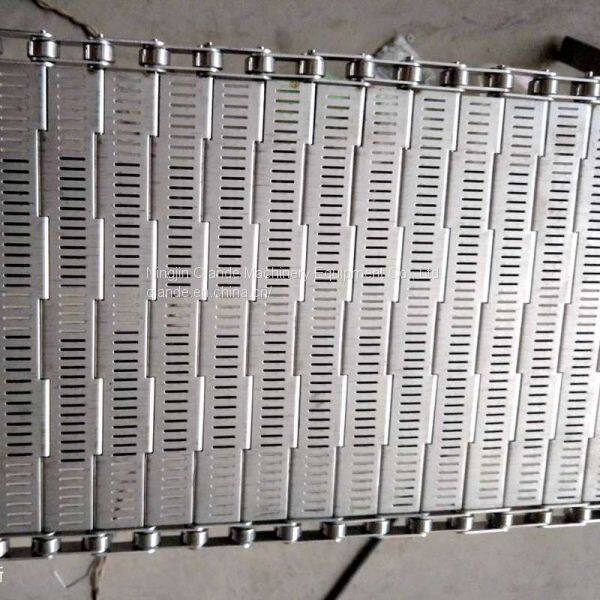

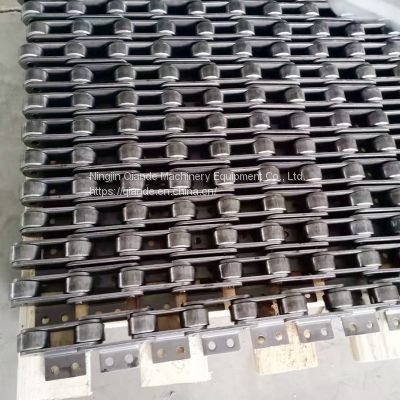

1. Inspect the chain plate surface for material residues or oil buildup, and promptly clean with water or a specialized cleaner to prevent residue from jamming the chain.

2. Monitor the conveyor belt's operation to detect issues like misalignment, vibration, or abnormal noises. If misalignment is detected, promptly adjust the sprocket or tensioning mechanism.

3. Check for looseness in the pin and chain joints. If any looseness is found, tighten them immediately to prevent the chain plate from falling off.

4. Monitor the temperature and noise levels of the drive motor and sprocket. If abnormal overheating or unusual noises are detected, immediately shut down the machine for inspection.

II. Weekly Maintenance Items

1. Apply specialized lubricants to transmission components (e.g., sprockets, chains) to ensure smooth operation. Avoid using acidic lubricants for stainless steel conveyor belts, while plastic conveyor belts require lubricants compatible with their material.

2. Inspect the chain plate for deformation, cracks, or excessive wear. Mark and replace any damaged sections immediately.

3. Clear dust and debris around the equipment to maintain a clean operating environment and prevent foreign objects from being caught in the conveyor belt.

III. Monthly Maintenance Items

1. Conduct a comprehensive inspection of the tensioning device's tightness, adjust the tension according to the conveyor belt's elongation, ensure uniform tension, and prevent belt misalignment from excessive slack or excessive tension that may cause accelerated wear.

2. Perform rust prevention inspection on stainless steel conveyor belts. If localized rust is detected, clean with rust remover and apply rust preventive oil. Inspect plastic conveyor belts for signs of aging or brittleness.

3. Adjust the conveyor belt speed to match the production line's rhythm, preventing overspeed operation that may shorten its lifespan.

IV. Special Precautions

1. Dedicated conveyor belts for food/pharmaceutical industries: After cleaning, sterilization must be performed. The use of residual cleaning agents is strictly prohibited to prevent contamination of materials.

2. Conveyor belt for high-temperature conditions: After shutdown, allow the equipment to cool naturally before cleaning and maintenance to prevent equipment damage or burns from high temperatures.

3. Plastic conveyor belt: Avoid contact with sharp materials, high-temperature heat sources, and strong acids or alkalis to prevent chain plate scratches, deformation, or corrosion.

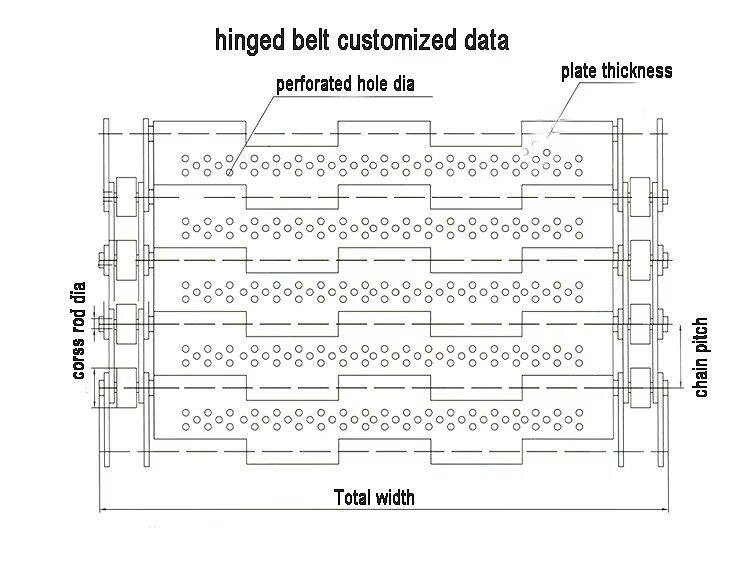

1. Precise requirement alignment: Foreign clients must specify core procurement parameters including stainless steel grades (304/316/314 etc. for high-temperature and corrosion-resistant applications), mesh tape specifications (pitch, wire diameter, pitch, wire diameter and total length, width), weaving type, accessories (side baffles, anti-slip patterns), along with application scenarios (food processing/metallurgical/construction materials), operating conditions (temperature, load capacity), and batch requirements.

2. Supplier Qualification Verification: Clients may verify domestic suppliers' production credentials (e.g., ISO9001 certification), import/export authorization, production capacity, and industry reputation through B2B platforms, trade exhibitions, or third-party certification bodies. When required, clients may also request proof of prior cross-border collaboration or client references.

3. Preliminary Proposal & Quotation: The supplier shall provide customized technical solutions and a preliminary quotation (including unit price and packaging fees) based on client requirements, specifying the minimum order quantity and estimated production cycle. The quotation shall clearly indicate the currency type (typically USD/EUR) and validity period, and specify whether additional charges such as customs duties and transportation fees are included.

II. Sample Confirmation and Cooperation Negotiations

1. Sample Request and Testing: The client may pay for sample fees and international shipping costs to request physical samples from the supplier. Key parameters such as material purity, structural stability, and dimensional accuracy will be tested to ensure compliance with usage requirements. Should any parameter adjustments be required, both parties shall promptly communicate to optimize the solution.

2. Commercial Terms Negotiation: Both parties shall agree on key cooperation terms, including product quality standards (complying with international standards or the client's country's technical specifications), delivery schedule, payment methods (commonly T/T, L/C, and other cross-border payment methods), liability for breach of contract, and dispute resolution (international arbitration is recommended).

3. On-site inspection (optional): For large orders, clients may engage domestic representatives or third-party agencies to conduct on-site evaluations of suppliers' production facilities, equipment configurations, quality control processes, and production capacity, to verify compliance with order specifications.

III. Contract Signing and Advance Payment

1. Formal Contract Execution: Both parties shall execute a bilingual (Chinese-English) cross-border procurement contract, specifying key terms including product specifications, quantities, total value, payment schedule (e.g., advance payment ratio and final payment terms), delivery locations (shipping/destination ports), packaging standards, and inspection procedures. The contract must comply with the United Nations Convention on Contracts for the International Sale of Goods and the trade regulations of both parties' respective jurisdictions.

2. Advance Payment: The customer shall pay an advance payment (typically 30%-50% of the total amount) as stipulated in the contract, and provide payment documentation promptly upon receipt. The supplier shall then initiate production scheduling and raw material procurement immediately after receiving the payment.

IV. Production and Manufacturing Progress Tracking

1. Customized Production: Suppliers process raw materials (including wire winding, braiding, and edge reinforcement) based on confirmed technical parameters, strictly adhering to quality control standards throughout production, with sampling inspections conducted at critical stages.

2. Real-time progress tracking: Suppliers shall submit regular production progress reports to clients (with attached production site photos/videos). In case of raw material shortages or technical adjustments, immediate communication and solution coordination shall be conducted to prevent delivery delays.

3. Finished Product Inspection: Upon completion of production, the supplier shall conduct a comprehensive quality inspection of the mesh tape (including dimensional verification, corrosion resistance testing, and visual inspection), while removing surface oil residues and impurities to ensure compliance with contractual specifications. A quality certification will be issued upon successful inspection.

V. Packaging, Logistics, and Customs Clearance Preparation

1. Standard export packaging: Customized packaging solutions (e.g., plastic sealing with wooden crates) shall be implemented based on conveyor belt dimensions and transportation requirements, featuring moisture-proof, wear-resistant, and deformation-proof features. The packaging must clearly display product name, quantity, weight, shipping marks, and safety warnings including "Handle with care" and "Moisture-proof" to ensure secure cross-border transport.

2. Logistics Plan Confirmation: The parties shall negotiate to select the most suitable international transport mode (maritime shipping offers better cost-effectiveness for bulk orders, while air freight provides faster delivery for urgent shipments). The departure port (e.g., Shanghai Port or Shenzhen Port) and destination port shall be finalized. The supplier shall assist in contacting certified international logistics providers to confirm transportation costs and estimated arrival time.

3. Customs clearance documentation: The supplier assists the client in preparing complete customs clearance documents, including commercial invoices, packing lists, bills of lading, certificates of origin, quality certificates, and import/export licenses (if required), ensuring all document information is consistent and complies with the client's country's customs clearance requirements.

VI. Payment of the Final Amount and Delivery of Goods

1. Final Payment: Upon receiving the supplier's stock completion notice and supporting documents, the customer shall make the final payment as stipulated in the contract. The supplier shall arrange for cargo loading and dispatch upon confirmation of payment, and promptly provide the customer with the logistics tracking number and transportation route inquiry method.

2. Full-process logistics tracking: Throughout the transportation process, suppliers and logistics providers maintain constant communication to provide real-time updates on cargo status. In case of delays, damage, or other anomalies, they promptly coordinate solutions and notify customers.

7. Customs Clearance, Acceptance and After-sales Service

1. Destination Customs Clearance: The customer submits the customs documents provided by the supplier to the local customs authority upon arrival of the goods, pays import duties, value-added tax (VAT) and other applicable taxes, and completes the clearance process (with assistance from a local customs broker if required).

2. Goods Inspection: Upon receiving the goods, the customer shall verify the quantity, packaging integrity, dimensional accuracy, and performance status against the contract and quality standards. If any quality issues or quantity shortages are found, the customer must take photographic evidence within the contractually stipulated inspection period and report to the supplier.

3. After-sales Service: The supplier provides a 1-2 year warranty covering non-human-induced quality defects, with complimentary repair or replacement services. Additionally, technical support is available to address installation, usage, and maintenance queries, and to resolve cross-border after-sales issues.

Recently Posted

-

High-Performance Ton Bag Buckle Conveyor: Your Ideal Heavy-Duty Conveying Solution

January 6, 2026High-Performance Ton Bag Buckle Conveyor: Your Ideal Heavy-Duty Conveying SolutionIn the fields of chemical, construction material Read More

Read More -

The cross-border application of conveyor chains under cultural differences

January 4, 2026In global trade, as the core component of industry, the application logic of the conveyor chain is deeply imprinted with the cultu Read More

Read More